i.Mechanized Methods

As discussed in preceding sections, traditional method of khoa making causes excessive strain and fatigue on the worker because milk has to be manually scraped and stirred continuously for long time by the worker standing near the heating source.The evaporation of moisture from milk and its subsequent condensing makes the surrounding hot and humid. To overcome these drawbacks, several mechanized systems have been developed from time to time. Most of these are broadly based on following two principles:

• In the first concept the agitator and scraping blades assembly is mechanically operated and the body of kettle is fixed/stationary.

• In the second principle, the mechanical scraping and agitation of milk is done indirectly by rotating the body of khoa making unit around the fixed agitator and scraper assembly.

The drawbacks of both the mechanized systems are a) they are batch type methods and b) cannot directly provide final desiccation to the khoa stage. When milk is thickened sufficiently (pasty stage), the mechanical agitation is not as efficient and some burning of milk solids occurs on heating surface. Hence, final product of desired texture is obtained by manual scraping. Out of the above two systems the one based on the principle of rotative body of the unit with fixed scraper assembly is more common among small traders in many parts of the country.

ii.Continuous Methods

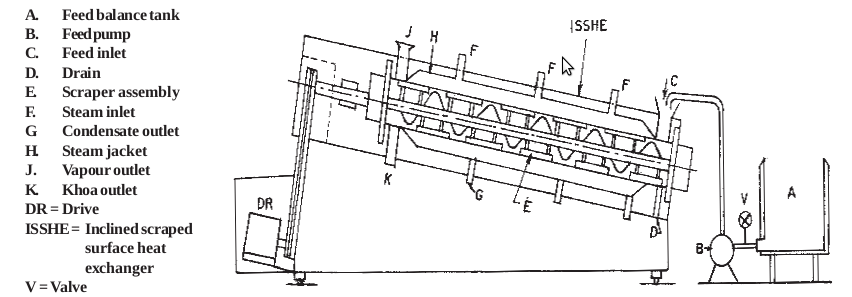

Several types of prototype machines have been designed for continuous manufacture of khoa in the past. Many of these units could not be commercially adopted by dairy industry because of some drawbacks. The most successful and presently being used are inclined scraped surface heat exchanger (ISSHE) and thin film scraped surface heat exchanger (TSSHE).Inclined scraped surface heat exchanger: ISSHE unit was developed at the National Dairy Development Board, Anand for continuous manufacture of khoa.The unit comprises of a feed balance tank, a positive displacement pump and a scraped surface heat exchanger in inclined configuration (0-30o). The feed tank is made up of stainless steel and has a capacity of 50 litres. A variable capacity feed pump is used to provide the milk concentrate to the ISSHE at the desired flow rate.The heat exchanger comprises of inner cylinder, rotor and drive, and outer steam jacket. The inner cylinder is in S.S. construction and forms the main body. It is provided with steam jacket and split into three separate compartments. The steam jacket is insulated and cladded. The design of rotor is the key factor in this innovation.It combines the functions of scraping and conveying the product. The rotor is driven by a variable speed drive. The constructional features of ISSHE are shown in

|

| ISSHE Continuous Khoa Making Plant |

Concentrated milk having 40-45% total solids is pumped into the inlet of the ISSHE at the desired flow rate by adjusting the capacity of the feed pump. At the start of the operation, the inclination of ISSHE permits formation of a pool of boiling milk,critical for development of desired heated or slightly cooked flavour in khoa.Subsequently, fresh concentrated feed enters the pool of boiling concentrates, while an equivalent mass continuously leaves the pool as semi-solid mass (khoa). The scraper repeats the process of removing coagulated particles from the heat transfer surface and mixing them back into the pool of heated milk. The coagulated particles absorb milk resulting in the agglomeration and formation of characteristic khoa texture. The inclination of the scraper provides interface between metal, milk and air, which enhances the heat coagulation of proteins which is essential for simulating desired flavour and texture in khoa. The process of khoa making as it takes place in a karahi is replicated in the ISSHE. The wet coagulated particles are pushed ahead by the screw conveyer. At the end of the process run, supply of concentrated milk is

stopped and warm water is circulated. It can produce about 40 kg khoa per hour,but installing more such units can increase the capacity.

Thin film scraped surface heat exchanges: TSSHE unit for continuous manufacture of khoa was developed at National Dairy Research Institute, Karnal.The constructional features of this unit have been shown in Fig. 2.3. In this unit, the two SSHEs are arranged in a cascade fashion. The rotor of the first SSHE is provided with four variable clearance blades and operated at 200 rpm. Standardized buffalo milk is concentrated in this SSHE in the range of 40-45 per cent T.S. This concentrated milk then enters the second SSHE, which has a different kind of rotor arrangement.It has two variable clearance blades and two helical blades, which operate at a speed of 150 rpm. Both the SSHEs are double jacketed and fitted with steam supply line, pressure gauze and vapour outlet. Contrary to the ISSHE, the cylinders in this unit are placed horizontally, one after the other. Milk is fed into first SSHE with a centrifugal pump, whereas, the concentrated milk from first SSHE to second SSHE moves by gravity. It can produce about 50 kg of khoa per hour

stopped and warm water is circulated. It can produce about 40 kg khoa per hour,but installing more such units can increase the capacity.

Thin film scraped surface heat exchanges: TSSHE unit for continuous manufacture of khoa was developed at National Dairy Research Institute, Karnal.The constructional features of this unit have been shown in Fig. 2.3. In this unit, the two SSHEs are arranged in a cascade fashion. The rotor of the first SSHE is provided with four variable clearance blades and operated at 200 rpm. Standardized buffalo milk is concentrated in this SSHE in the range of 40-45 per cent T.S. This concentrated milk then enters the second SSHE, which has a different kind of rotor arrangement.It has two variable clearance blades and two helical blades, which operate at a speed of 150 rpm. Both the SSHEs are double jacketed and fitted with steam supply line, pressure gauze and vapour outlet. Contrary to the ISSHE, the cylinders in this unit are placed horizontally, one after the other. Milk is fed into first SSHE with a centrifugal pump, whereas, the concentrated milk from first SSHE to second SSHE moves by gravity. It can produce about 50 kg of khoa per hour

|

| Thin Film Scraped Surface Heat Exchanger for Continuous Khoa Manufacture |

Advantages of continuous khoa making plants

• As the process is continuous, the product of uniform quality with low operation losses is produced throughout the run.

• Higher heat transfer coefficient, so fuel consumption is considerably less.

• It is easy to go in for automation.

• The plant is suitable for cleaning-in-place (CIP).

• Only one man can handle the unit without much fatigue.

• Sanitary operation as process takes place in a completely closed environment.

Disadvantages

• Unsuitable for small entrepreneurs

• The initial cost is high.

• Trained operator is required to run the plant.

• The ISSHE unit requires concentrated milk, having 40-45% TS as feed, hence cannot be adopted where concentrated milk is not available.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.